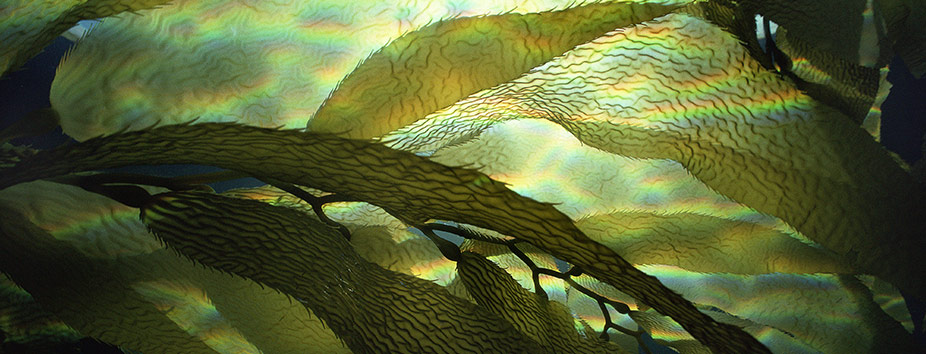

Seaweed: much more than sushi

Seaweed may become a key market for Australian aquaculture as research and development investigates applications far beyond wrapping rice.

Seaweed may become a key market for Australian aquaculture as research and development investigates applications far beyond wrapping rice.

Words: Leanne Tomkins

It may surprise you to learn that seaweed extracts are regularly used as gelling agents and thickeners in many daily products. Shampoo, make-up, baby formula, salad dressing, wound coverings and chocolate milk all utilise these versatile aquatic plants, and potential uses are arising in even stranger places.

In a 2014 report into the seaweed industry, the Rural Industries Research & Development Corporation (RIRDC) stated: "Australia has the capacity and is positioned to establish a unique profile of quality and high-value applications of seaweed biomass and its diverse products."

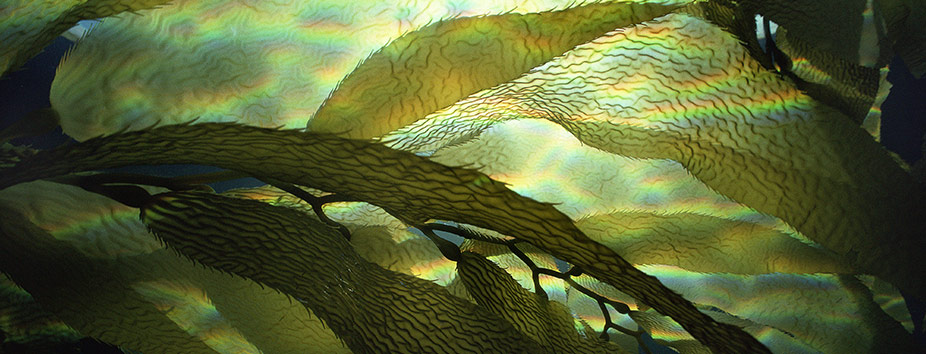

The Australian seaweed industry is still in its infancy, but our country's plentiful coastline, unpolluted oceans and diverse seaweed flora-more than 2000 species, many unique-give us a natural advantage, one that foreign companies are already taking an interest in.

"I think there's great potential for an export market, but I also think there's huge potential for a domestic market," said Dr Alecia Bellgrove, a Senior Lecturer at Deakin University involved in native seaweed harvesting trials off the Victorian coast.

"We've had some interest from some Chinese investors and some Taiwanese importers/exporters," she told the ABC, "… because [Australian seaweed is] theoretically a much cleaner product than seaweeds grown in other parts of the world."

This year China's second-largest seaweed processor, Gather Great Ocean Group (GGOG), intends to make the most of Australia's clean, green produce. It has purchased SA company Australian Kelp Products, maker of seaweed-based fertilisers and supplements for livestock.

GGOG plans to invest $21 million in the operation over the next three years, creating 200 local jobs in the process, and has commissioned researchers at Flinders University to develop new technologies to extract marine sugars, which are widely used as gelling agents in the food and pharmaceutical industries.

According to Flinders University's Professor Wei Zhang, who began conversations with GGOG in 2012, Australia's rigorous environmental guidelines mean that much of the technology used for seaweed farming overseas cannot be used here.

"We have more strict environmental regulation," he told the ABC. "So we're developing even better and environmentally friendly technology."

Given the UN Food and Agriculture Organization (FAO) estimates worldwide seaweed production grew by 9.7 per cent to 26.1 million tonnes in 2013, and Australia currently imports about $20 million worth of seaweed annually, the potential market for Australian-made seaweed products is considerable.

Seaweed has a longstanding history of agricultural use in fertilisers, soil conditioners and nutritionally enhanced animal feed, but trials in 2014 at Pacific Reef prawn farm in North Queensland have proven another use for the nitrogen-consuming plants: treating wastewater.

MBD Energy, the company behind the technology, intends to expand into other commercial-scale agricultural ventures such as piggeries, poultry farms and dairy operations this year.

Arguably, one of the most exciting potential applications for seaweed and algae is biofuels. Compared with corn, seaweed grows faster; produces 20 times more biofuel per hectare; can safely grow in non-potable water; is carbon neutral; produces oil year-round; and can be farmed on non-arable land, including desert, so it doesn't compete with a region's food production. Compared with palm oil, algae can produce 10 times more oil on 10 times less land, making it significantly more environmentally friendly.

Algal biodiesel production facilities are already established in many Australian states, although most are still in the research phase.

The Australian Government has committed $20 million to investigate biofuels, $5 million of which has been allocated to James Cook University to establish a demonstration-scale facility in Queensland to produce biocrude-a base for high-energy fuels-from seaweed.

Similarly, biofuel company Algae.Tec is growing micro-algae in Nowra, NSW, to be converted into fuel for the transport industry. The company estimates that its algal system could produce biocrude at a cost of US$35-40 per barrel-about half the price of oil.

The medical industry is also exploring innovative uses for seaweed extracts. 3D bioprinting is particularly intriguing; it combines 3D printing technology-which prints objects based on digital models-with biopolymers extracted from seaweed to create 3D-printed tissues suitable for transplant into humans.

While printing fully functional human organs-hearts, kidneys and so on-is still a challenge for the future, several:

"Companies are already printing living human tissues for body parts, such as ears and noses, using seaweed-based biopolymers."

Recently, in NSW, marine scientists at the University of Wollongong's Intelligent Polymer Research Institute launched a 3D printing BioPen, which ejects layers of 3D tissue created from the patient's own stem cells, supported by a structural component partially built from seaweed extract. This allows orthopaedic surgeons to repair damaged bone material at the time of surgery.

While the future of this fledgling industry looks promising, it will require continued investment in research and development to realise its full potential.